The Audi 5 Cylinder 10V Turbo engine is a remarkable piece of engineering known for its performance and reliability. A key component of this engine’s success is its valve system, which includes valve shims. These small but crucial parts play an essential role in the performance and longevity of the engine. This article explores the importance of valve shims, their function, and how to maintain them for optimal engine performance.

What Are Valve Shims?

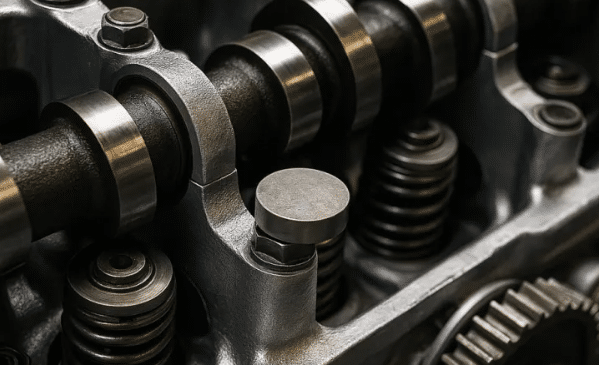

Valve shims are small, round metal discs that sit between the valve lifter and the valve stem. Their purpose is to adjust the clearance between the valve and the lifter, ensuring the engine runs smoothly. Without the proper clearance, the engine could experience misfires, poor performance, or even damage over time.

Why Are Valve Shims Important in the Audi 5 Cylinder 10V Turbo Engine?

In the Audi 5 Cylinder 10V Turbo engine, valve shims are critical for maintaining optimal valve timing and ensuring the engine’s smooth operation. The engine’s performance is highly dependent on the precise timing of the valve opening and closing. If the valve clearance is incorrect, it could lead to a range of problems, including reduced engine efficiency, misfires, and even valve damage.

How Do Valve Shims Work?

Valve shims adjust the gap or clearance between the valve and the lifter. This gap is essential because it compensates for wear and tear that occurs over time as the engine operates. When valve shims are installed properly, they allow for smooth valve operation and help maintain the engine’s overall efficiency. The right thickness of a valve shim ensures that the valve opens and closes at the correct time, which is vital for engine performance.

Types of Valve Shims in the Audi 5 Cylinder 10V Turbo Engine

There are different types of valve shims used in the Audi 5 Cylinder 10V Turbo engine. These include:

- Standard Shims: These are the most common types of valve shims. They come in a variety of thicknesses to accommodate different engine requirements.

- Adjustable Shims: These shims can be adjusted to different thicknesses, providing more flexibility in achieving the desired valve clearance.

- Bolt Shims: These specialized valve shims have bolts attached to them for specific applications where more precise adjustments are needed. They are typically used in high-performance engines and in situations where precision is critical.

Symptoms of Worn or Damaged Valve Shims

Over time, valve shims can wear down or become damaged, leading to several noticeable symptoms. Some of the common signs include:

- Rough Idle: If the valve clearance is off due to worn valve shims, the engine may idle roughly. You might notice that the engine feels unstable at low RPMs.

- Engine Misfires: Incorrect valve clearance can lead to misfires. This happens because the valves are not opening or closing at the proper times, which disrupts the air-fuel mixture.

- Poor Acceleration: If the valve shims are worn or damaged, the engine may lose power and fail to accelerate smoothly.

- Increased Engine Noise: A noisy engine could be a sign of improper valve clearance, which is often caused by worn valve shims. The noise may sound like ticking or tapping.

- Reduced Performance: If valve shims are worn, the engine’s performance will suffer. This could manifest as reduced power, less responsiveness, and decreased fuel efficiency.

How to Maintain Valve Shims

Regular maintenance is essential for the health of your Audi 5 Cylinder 10V Turbo engine. Below are some tips on maintaining valve shims:

- Check Valve Clearance Regularly: Checking the valve clearance at regular intervals is essential to ensure that the valve shims are functioning properly. This is typically done during scheduled engine maintenance or servicing.

- Replace Worn Shims: If you notice any of the symptoms mentioned above, it may be time to replace the valve shims. Replacing them will restore the engine’s performance and prevent further damage.

- Use High-Quality Valve Shims: Always opt for high-quality, OEM (Original Equipment Manufacturer) valve shims. These parts are designed specifically for your engine, ensuring the best possible fit and function.

- Proper Installation: Valve shims must be installed with care. It’s crucial to use the correct tools and follow the manufacturer’s guidelines to ensure proper installation and alignment.

- Monitor Engine Performance: After replacing valve shims, monitor your engine’s performance closely. If any issues arise, you may need to adjust the shims further.

How to Choose the Right Valve Shims for Your Audi 5 Cylinder 10V Turbo Engine

Choosing the correct valve shims is essential for maintaining engine performance. Consider the following when selecting valve shims for your Audi 5 Cylinder 10V Turbo engine:

- Thickness: The thickness of the valve shims must match the requirements of your engine. Too thick or too thin a shim could cause improper valve clearance, affecting performance.

- Material: Valve shims are typically made from high-quality steel or other durable materials. Be sure to choose shims that are made from materials designed to withstand the high temperatures and stresses found in the engine.

- OEM Parts: For the best performance and longevity, always choose OEM valve shims. These parts are designed to work seamlessly with your Audi 5 Cylinder 10V Turbo engine.

The Role of Bolt in Valve Shim Systems

While valve shims themselves are critical, the bolt plays a key role in securing the shims in place. Without a properly installed bolt, the shims may shift, causing further engine problems. It’s essential to ensure that the bolts are tightened correctly to avoid any movement or misalignment. Using high-quality bolts designed specifically for the Audi engine is essential for maintaining the integrity of the valve system.

Conclusion

Valve shims are essential components in the Audi 5 Cylinder 10V Turbo engine, ensuring that the engine runs smoothly and efficiently. They help maintain proper valve clearance, prevent misfires, and reduce engine wear. Regular maintenance, such as checking valve clearance and replacing worn shims, is vital for keeping the engine in top condition. By using the right valve shims and ensuring correct installation, you can extend the life of your Audi engine and enjoy a smoother, more powerful ride.

Frequently Asked Questions

How often should I replace the valve shims in my Audi 5 Cylinder 10V Turbo engine?

Valve shims should be inspected regularly as part of routine maintenance. They may need replacement if you notice symptoms such as rough idling, engine misfires, or increased engine noise.

Can I replace valve shims myself?

Replacing valve shims requires a certain level of technical skill and specialized tools. If you are not familiar with engine repairs, it is recommended to have a professional mechanic handle the replacement.

What happens if the valve shims are not replaced in time?

If valve shims are not replaced, it can lead to improper valve clearance, which can cause engine misfires, poor performance, and even severe engine damage over time.

Are aftermarket valve shims a good option for my Audi engine?

While aftermarket valve shims may be cheaper, it’s always recommended to use OEM (Original Equipment Manufacturer) parts for the best performance and compatibility.

What is the role of the bolt in the valve shim system?

The bolt secures the valve shims in place. If the bolt is not properly installed or tightened, it could lead to misalignment and further engine issues. Always ensure the bolts are tightened to the manufacturer’s specifications.